The UK has opened a competition to find the small modular reactor of the future, and ENEL is already concluding agreements for their future production. The Natrium project, funded by Bill Gates, is aiming for a similar niche.

The popularity of the "small atom" is easily explained: Solar and wind power plants produce electricity too intermittently to hope for a carbon-free transition without the support of atomic energy.

However, a careful analysis of the prospects for such systems leads to the disappointing conclusion that they have almost no chance of success. What could be a reasonable alternative?

The carbon-free transition in the Western world of the 21st century has so far relied on wind farms and solar panels. However, scientific papers show that solar generation cannot play a key role here: The production of photovoltaic cells in a temperate country in December is an order of magnitude less than in July. To store their energy for six months would require an enormous battery capacity.

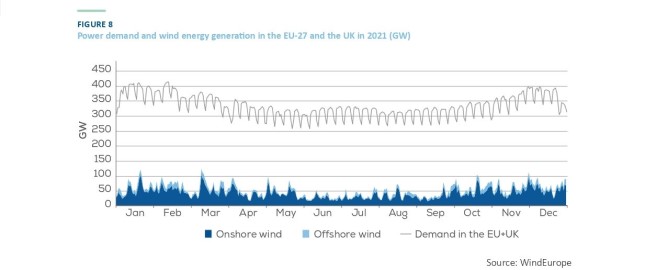

2022 data. The dotted line shows the total wind power capacity in the EU and UK (236 gigawatts). It is easy to see that during winter peaks in energy demand, wind turbines can run for weeks at less than 10% of their nominal capacity, and batteries capable of storing energy for half a month for all of Europe would cost tens of trillions of dollars.

But all is not well with wind turbines either. The experience with them in the EU, where in 2022 they produced 15% of the total generation, shows that this generation is too unstable. Frosty and windless two-week-long anticyclones are typical for local winters. Energy consumption for heating is maximal, while the output is minimal. Alternative carbon-free sources are needed.

A small water reactor

Not surprisingly, the UK has opened a competition to find the small modular reactor of the future, and ENEL is entering into an agreement for their future production. Why the Western world specifically chose the small reactor is not hard to understand. French and American nuclear engineers build 15-20 years' worth of GWRs (Olkiluoto 3) at a cost of EUR 11 billion. This contrasts sharply with 4-5 years of construction of reactors of the same capacity in the PRC and Russia, but Western companies cannot order reactors there, which means large gigawatt power units are too expensive for them.

Small modular reactors take a fundamentally different approach. For example, the SMR-160 project by the American company Holtec has a capacity of only 160 megawatts – an order of magnitude smaller than Olkiluoto 3. Therefore, it should be built in just three years (six times faster).

To avoid Fukushima-type problems, such nuclear power plants are completely devoid of pumps. So if a tsunami or other disaster were to cut off the plant's external power supply, the reactor would not overheat because the pumps that pump the cooling water to it would stop.

This level of safety is called "walk-away safe," and has significant positive economic consequences. If there is no risk of overheating, there is no need for boron braking of the reactor during abnormal operation. Without boron, the reactor vessel steel would not corrode; the SMR-160, without boron, is expected to last 80-100 years. For large modern reactors with boron braking, it is only 60-80 years.

But everything comes at a price. For a reactor to be cooled without pumps, by natural circulation due to warm water rising upwards, it has to be designed specifically for the slow movement of cooling water, meaning the reactor is larger than the same power reactor with pumps, and thus more expensive. Developers are targeting a price of USD 1 billion apiece – USD 6,660 per kilowatt of installed power.

The pump-operated Russian VVERs at Turkey's Akkuyu nuclear power plant are being built at USD 2.75 billion apiece, which is more than USD 2,300 per kilowatt of capacity. The cost of construction accounts for at least 60% of the price of energy from nuclear power plants. Consequently, the SMR-160 will produce electricity at least twice as expensive as conventional nuclear power plants outside the Western world.

The picture is similar for the reactors planned by ENEL or any other player. In this form, carbon-free transition is possible, but it will be very expensive, albeit cheaper than the creation of energy storage units for wind and solar power plants.

The sodium curse

Not surprisingly, the Bill Gates-backed startup Terra Power has decided to approach the problem from a different angle. Instead of small water reactors, it is planning a small 345-megawatt Natrium sodium reactor.

Its advantages over a water-cooled reactor are obvious. Liquid sodium has an enormous heat capacity and thermal conductivity, so such a reactor can be made much smaller than a water-cooled reactor. In addition, it boils at almost 900 degrees Celsius, unlike water. The latter even under very high pressure boils before 400 degrees. That is why the pressure in a sodium reactor is about one atmosphere, and in a water reactor – up to 160 atmospheres.

The thickness of a steel reactor vessel for 160 atmospheres is 20 centimeters. Clearly, this can only be done with unique and very expensive equipment. It is planned to make the Natrium vessel of standard 40mm steel, which costs incomparably less.

But the disadvantages of sodium are no less obvious. Such reactors have been tried in the USA, France, and Japan, and they caught fire everywhere they were tried: In contact with air, water, and concrete, sodium reacts violently. Simply put, it burns, and it is virtually impossible to put the fire out.

Without burning out sodium, BN reactors only worked in the USSR and Russia, and now a very similar reactor is being built by China (with the support of Rosatom). There is no successful long-term experience of this kind with sodium reactors in the West. There will have to be many small modular reactors – hundreds for any large country; thousands for, say, the US. Fires will be inevitable, and that casts doubt upon the economy of reactors.

Is there a ford in the fire?

It all looks like a dead end: Small water reactors are too expensive, small sodium reactors are too inflammable. Russian nuclear specialists have already raised and answered this question. First, other coolants can be used, such as lead-bismuth, which does not require high pressure and a thick casing, but does not burn like sodium. Second, it is possible to replace every tenth atom in the cooling sodium melt with lead, which would mean the sodium would not burn in the air.

Another thing is that these answers are not particularly in demand in Russia or China. They successfully build large NPPs using water there, which is why they do not particularly want to master the new designs of small modular reactors.

In the Western world, the picture is different: Due to decades of anti-nuclear sentiment, large reactors cannot be built on time or cheaply. Local startups should take a closer look at the solutions previously considered in Russia.

Alas, the practical probability of this is about zero. Russia has been working with lead-bismuth for decades, and nuclear submarines have floated with such reactors. There is no such experience in the US and Europe. A startup will not spend years doing fundamental science on stands (like they did in the USSR with metal coolants) in order to create a brand-new design.

On the contrary: Holtec, Terra Power, and others are trying to take designs that have been tested in the USA. After all, R&D on new coolants will take years, which would bury the prospects for commercialization for the foreseeable future.

As sad as it is, it looks like Western companies will have to master the art of building new large reactors (using old, water-based technologies) quickly again. As difficult as it may be, this option is much easier than the technological leap to sodium-lead or lead-bismuth.